How to increase fabrication efficiency

Some of the factors that can determine whether a fabrication shop lives or dies are out of the owners’ and shop managers’ control. Which makes it that much more important that they handle the factors that are in their control, and one of those factors that can make or break a shop is their fabrication efficiency. Usually when you think about how efficient your shop is you are thinking of the dollar cost of getting your countertops and custom stone work out the door. We’re going to talk today about some of the things involved in increasing your shop’s fabrication efficiency so that you can save money and grow your business.

One of the key factors involved in fabrication efficiency is the flow of the production. Increasing shop and fabrication efficiency by eliminating unnecessary costs (both money and time) is what shop owners and shop managers need to do, especially in fabrication shops that work on tight margins (which in our experience is ALL of them). A recent round-table forum about increasing shop efficiency had been made with the Stone Fabricators Alliance (SFA) members. According to the members who participated in the conducted forum, focusing on staging of basic material is a very great help in increasing of the shop efficiency.

Steps being taken today for fabrication to increase efficiency

-

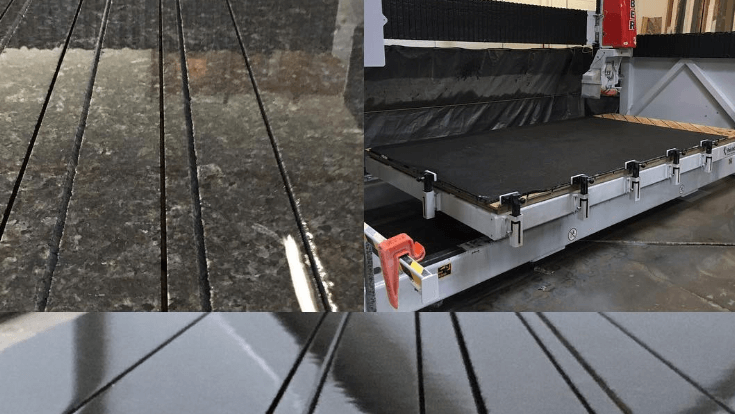

Material staging – this seems to be just very basic but very effective, many of stone fabrication shops do not consider material staging as a necessary part of their operation. It can be a HUGE and expensive pain to move existing racks and equipment around to optimize the material staging, but we’ve never seen a shop owner do it and then regret it. It is always a good idea. Staging the source material (raw stone slabs) close to the saw is the first step to improve the efficiency of the workflow and granite cutting process. Take all the slabs that needs to be cut tomorrow and stack them on an A-frame right next to the granite saw, so that when the saw finishes one slab the operator can easily grab another one and continue until none remain. The alternative, and far too common reality, is spending time digging through the slab yard for the next job’s slab. Even if it only takes ten minutes to look for slab around the yard can be a big waste of time. Time that could have been spent cutting out the next top.

-

Maintaining proper material flow – as the shop expands and equipment is added or removed the material flow can get complicated and convoluted. The once linear workflow is now a hopscotch affair because you expanded into a new shop and put your brand new CNC machine there and now your workers are walking slabs back and forth, wasting time. Even though shops have made a lot of technology investments over the years, they should maintain a linear work flow (work should flow only in one direction). This is easy to say and sometimes hard to do, especially when that new CNC machine is so heavy you had to dig up your shop floor and install rebar reinforced concrete just to support it and you feel like you can’t justify the expense to move all your equipment. We understand this, but we’re talking best practices here and that means an organized flow of material through your shop. When we say production should be linear, material comes from one end of the shop and the finished product goes to the other end. Handling of materials should be kept to minimum, the work flows forward, and nothing should be allowed to go backwards.

-

Material handling – As mentioned above, designing your shop to minimize how much the materials need to move as they get fabricated is critical. After that, you need to pick tools that can move the stone between stations as fast as possible. Using modern technology such as an overhead crane is great for moving slabs and finished tops easily over long distances, but it is expensive. A less expensive alternative is to use jib cranes. If you can design your work flow so that pivoting jib cranes can advance the tops through their stages, you won’t have to waste time loading and unloading stone onto rolling A-frames. Obviously, A-frames are great for storing completed jobs together in one place (preferably right next to the install truck that will install the job), but you don’t want your workers having to load and unload A-frames in between fabrication steps if you can avoid it. Cutting the number of times you have to load a piece to sit on an A-frame increases your shop’s efficiency.

-

Having the right tools for the job – This is where we come in at Basic Diamond. We have the right tools to get your jobs done quickly because we know what it takes to cut and finish the stone you’ve got in your shop. We work with some shop managers who think they’re doing the owners a favor by not buying a blade that is purpose built for the job at hand. They think they a stone blade is a stone blade is a stone blade and that it’s a waste of money to buy a blade (like the Assault QTZ) just to cut their quartzite jobs. The reality is it is ALWAYS WORTH THE MONEY. Save your owners money by using the right blade which will save your guys’ time in the shop and wear and tear on the machines.

The concepts mentioned above are only four of the many ways to increase shop fabrication efficiency at your shop.

Let us know if you have any questions about how we can tool your shop to get the job done faster and better.